Pulps——Determination of water

retention value (WRV)

编辑:弗艾博纤维技术研究中心

P tes - Determination de la valeur de retention d'eou (VRE)

tes - Determination de la valeur de retention d'eou (VRE)

Contents

Foreword……………………………………………………………………………iv

Introduction ………………………………………………………………………………………V

1.Scope ………………………………………………………………………………………1

2.Normative references ………………………………………………………………………………………1

3.Terms and definitions……………………………………………………………………… 1

4.Principle……………………………………………………………………… 1

5.Reagents……………………………………………………………………… 1

6.Apparatus……………………………………………………………………… 2

7.Sampling…………………………………………………………………………3

8.Preparation of sample………………………………………………………………………………3

9.Procedure……………………………………………………………………… 3

9.1General………………………………………………………………………3

9.2Forming in a Buchner funnel…………………………………………………………………………… 3

9.3Centrifuging the test pad…………………………………………………………………………………3

10.Calculation……………………………………………………………………4

11.Test report………………………………………………………………………………4

Annex A (informative) Test-pad-holding units………………………………………………………………5

Annex B (informative) Precision……………………………………………………………………………7

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is normally carried out through ISO technical committees. Each member body interested in a subject for which a technical committee has been established has the right to be represented on that committee. International organizations, governmental and non-governmental, in liaison with ISO, also take part in the work ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those Intended for its further maintenance are described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the different types of ISO documents should be noted. This document was drafted in accordance with the editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any patent rights identified during the development of the document will be in the Introduction and/or on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment, as well as information about ISO's adherence to the WTO principles in the Technical Barriers to Trade (TBT) see the following URL: Foreword . Supplementary information

The committee responsible for this document is ISO/TC 6, paper, board and pulps.

This second edition cancels and replaces the first edition (ISO 23714:2007) which has been revised to add a new precision statement that complies with the requirements of ISO/TR 24498.

Introduction

The water retention value (WRV) is an empirical measure of the capacity of a test pad of fibres to hold water. The WRV increases with increasing beating because of internal fibrillation, a widening of the small internal pores, and delaminations, which has been called "swelling" and which occurs concurrently with the development of external fibrils, which also serve to hold additional water.

This test can be useful for the pulp producer as a guide to the influence of the pulping process on the fibre produced and the papermaking potential of the pulp. It is also useful for the papermaker as a measure of the efficiency of pulping and refining

Pulps - Determination of water retention value (WRV)

1 Scope

This International Standard specifies a procedure for the determination of the water retention value (WRV) of all kinds of pulp.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are Indispensable for its application. For dated references, only the edition cited apples. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 5263-1, Pulps——Laboratory wet disintegration - Part 1: Disintegration of chemical pulps

ISO 5263-2, Pulps——Laboratory wet disintegration - Part 2: Disintegration of mechanical pulps at 20°C

IS0 5263-3, Pulps——Laboratory wet disintegration - Part 3: Disintegration of mechanical pulps at> 85°C

IS0 7213, Pulps——Sampling for testing .

IS0 14487, Pulps——Standard water for physical testing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

water retention value

ratio of the mass of water retained after centrifugation under specified conditions by a wet pulp sample

to the oven-dry mass of the same pulp sample

4 Principle

A test pad consisting of pulp fibres Is formed by dewatering a pulp suspension on a glass-fibre filter. The test pad is centrifuged under a specified centrifugal force for a specified time, weighed, dried, and weighed again. The WRV is calculated from the wet mass of the centrifuged test pad and the dry mass of the test pad.

NOTE The results obtained from a rewetted pulp will not be the same as those from a corresponding never-dried pulp.

5 Reagents

5.1 Standard water, as specified in IS0 14487.

If any other type of water is used, this shall be reported.

6 Apparatus

6.1 Laboratory centrifuge, with a swing-out head and buckets, made of an inert material such as steel or anodized aluminium, about 100 ml in volume, and about 45 mm in inner diameter.

The centrifugal force shall be (3 000土50) g (g is the acceleration due to gravity, i.e. 9,81 m/s2) at the position of the test pad, approximately 15 mm from the bottom of the bucket. The centrifuge shall be equipped with a timer and a brake.

It is desirable that the centrifuge should maintain a working temperature of (23土3) °C.

NOTE If g is the acceleration due to gravity, i.e. 9,81 m/s2, then the rotational frequency is obtained using Formula (1):

Where

N is the rotational frequency, in min-1 or r/min;

Z is the centrifugal force, (3 000 t 50) g;

r is the distance between the centre of rotation and the filtration plane of the glass filter (radius of gyra-tion), in metres.

6.2 B chner funnel or similar funnel, made of non-corrosive material, the perforated bottom ofwhich shall be flat, and having an internal diameter larger than 30 mm.

chner funnel or similar funnel, made of non-corrosive material, the perforated bottom ofwhich shall be flat, and having an internal diameter larger than 30 mm.

6.3 Wire cloth, of glass- fibre filter, e. g, Whatman grade GF/C filter or equivalent.

6.4 Suction flask, connected to a water suction pump or similar device for vacuum filtration applied to the Buchner funnel.

6.5 Set of test-pad-holding units.

The holding unit is a metal tube, (30土5) mm in inner diameter, with a phosphor-bronze wire screen attached to one end. The wire screen shall have a nominal size of aperture of 125 μm and a preferred diameter of the wire of 90 um. The centrifuge tube should be capped with a hole in the centre to prevent moisture loss.

The design of the holding unit depends on the design of the centrifuge and is therefore not specified in this International Standard. The unit shall fit into the centrifuge buckets in such a way that the test pad in the test-pad-holding unit will not be rewetted after centrifugation. Two examples of test-pad-holding units are described in Annex A.

The number of test pad-holding units required depends on the design of the centrifuge. All units shall have the same mass.

6.6 Weighing bottles with lids, having a volume of 25 ml.

6.7 Oven, capable of maintaining (105+2) °C. .

7 Sampling

If the test is being carried out to evaluate a pulp lot, the sample shall be selected in accordance with ISO 7213. If the test is made on another type of sample, report the source of the sample and, if possible, the sampling procedure used.

Make sure that the test portions taken are representative of the pulp sample.

8 Preparation of sample

If the pulp sample is in dried form, disintegrate the pulp in standard water (5.1) in accordance with ISO 5263-1 or ISO 5263-2.

If a mechanical pulp has been disintegrated at a temperature higher than 85 °C, in accordance with ISO 5263-3 to remove latency effects, then before proceeding further, the diluted stock sample shall be allowed to cool to (23土3)°C.

If the sample has been disintegrated, the disintegration method shall be stated in the test report.

Dilute the stock in standard water (5.1) to give a concentration in the range from 2 g/l to 5 g/l. For samples that drain slowly, use the highest concentration.

It shall be stated in the test report whether the sample is rewetted or never-dried, since there could be significant differences in the results.

9 Procedure

9.1 General

From the diluted and well-stirred stock, take samples and carry out WRV determinations at (23 +3) °C in duplicate. Carry out all determinations as soon as possible after sampling.

If, for practical reasons, WRV determinations are carried out a day or more after sampling, the WRV will be somewhat higher (normally less than 0,03 g/g) than it would have been if the determination had been carried out the same day. A n v significant dela v in carrving out the WRV tests shall be reported.

9.2 Forming in a B chner funnel

chner funnel

Connect the B chner funnel (6.2) to the suction flask (6.4). Put the glass-fibre filter in the funnel, moisten, and then start the suction. Add to the Bichner funnel a volume of the stock, so chosen that the test pad formed will have an oven-dry grammage of(1 700士100) g/m2, when placed in the test-pad-holding unit(6.5). .

chner funnel (6.2) to the suction flask (6.4). Put the glass-fibre filter in the funnel, moisten, and then start the suction. Add to the Bichner funnel a volume of the stock, so chosen that the test pad formed will have an oven-dry grammage of(1 700士100) g/m2, when placed in the test-pad-holding unit(6.5). .

For the volume of stock chosen, 100 ml of this volume should be filtered and then the suction stopped. If necessary (if the retention of fines is too low), add this initial filtrate to the remainder of the stock volume to be filtered.

Stop the suction when all the surface water has directly disappeared. The dry-matter content of the test pad should then be between 5 % and 15 %.

Remove the pad from the Buchner funnel and place it in a test-pad holder.

9.3 Centrifuging the test pad

Place the complete test-pad-holding unit with the test pad in a centrifuge bucket (see 6.1). Centrifuge at a speed that gives a centrifugal force of (3 000土50) g at the bottom of the pad for 30 min土30 s. This period shall include neither acceleration nor retardation.

The temperature of the test pad during the centrifugation can influence the result, and it is therefore recommended that the centrifuge be able to maintain a working temperature of (23土3)°C. Otherwise, the temperature of centrifugation should be included in the report. If multiple centrifuging tests are to be run, then some time should be allowed for the centrifuge to cool between each run, to be within the proper temperature range.

Immediately after the centrifuge has stopped, transfer the test pad to a preweighed weighing bottle(6.6). Weigh it to the nearest 1 mg. Place the open weighing bottle together with its lid in a drying oven (6.7) and dry to constant mass at a temperature of (105土2) °C (normally overnight). Close the weighing bottle and allow it to cool in a desiccator, raise the lid briefly to achieve pressure equalization, and weigh the closed bottle to the nearest 1 mg.

10 Calculation

Calculate the WRV, in grams per gram, using Formula (2):

Where

m1 is the mass of the centrifuged wet test pad, in grams;

m2 is the mass of the dry test pad, in grams.

Calculate the mean of the duplicates and report the result to two decimal places.

The results of the parallel determinations shall not differ by more than 5 % from their mean.

11 Test report

The test report shall include the following information:

a) a reference to this International Standard ( i.e. ISO 23714);

b) all information necessary for complete identification of the sample;

c the date and place of testing;

d) rewetted or never-dried pulp used;

e) the results, as specified in Clause 10;

f) any departure from this International Standard, or any other circumstances or influences regarded as optional, that could have affected the results.

Annex A

(informative)

Test-pad-holding units

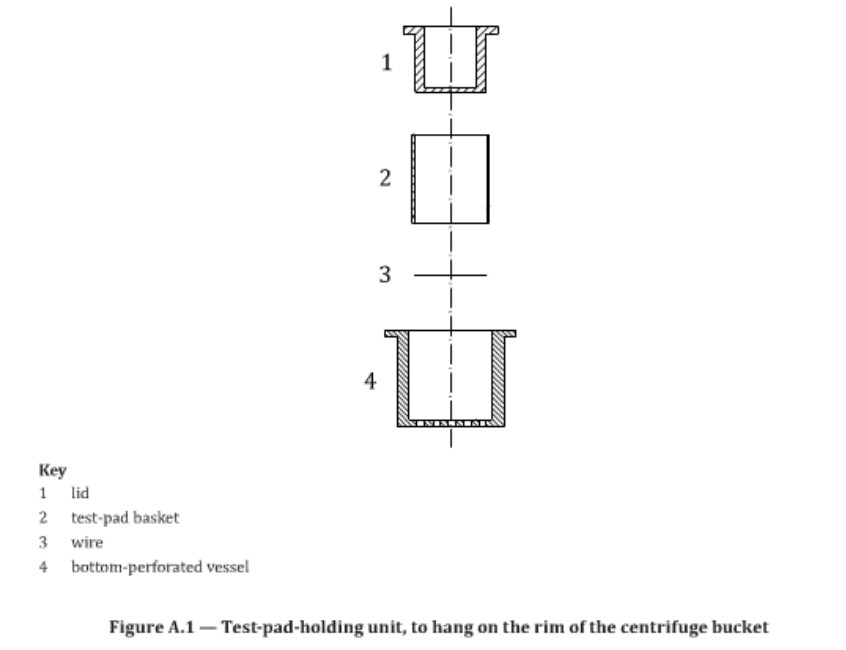

This informative annex describes examples of the design of two different test-pad- holding units.

A.1 Test-pad-holding unit, to hang on the rim of the centrifuge bucket

This kind of test-pad-holding unit (shown in Figure A.1]) has four parts: (2) is the test-pad basket with its wire (3). The wire is not soldered to the tube but is fixed in position by pushing the tube (2) into the vessel (4), which has a perforated bottom. The l d (1) fits into the tube (2) and forms a cover. It has a small hole to allow air to pass through. All parts are machined to fit tightly to each other. During centrifugation, the unit hangs on the rim of the centrifuge bucket, leaving enough space underneath to accommodate drained water.

The parts (2), (3), and (4) are assembled before adding the sample. The lid (1) is placed in position before centrifugation.

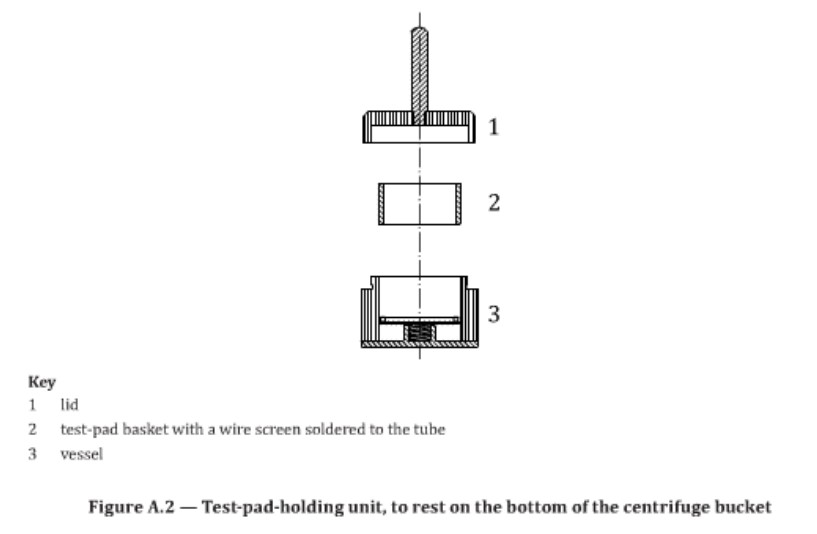

A.2 Test-pad-holding unit, to rest on the bottom of the centrifuge bucket

This kind of test-pad-holding unit (shown in Figure A.2) has the test-pad basket (2) and its wire screen: soldered to the tube. The basket fts into the vessel (3) where it rests on a flange. A circular metal plate is! pressed towards the flange from below by means of a spring, The plate acts as a non-return valve, which opens only when the centrifuge runs at full speed, thus preventing any rewetting of the pad when the centrifuge Is stopped. The lid (1) fits onto the vessel (3) and has a handle to facilitate its removal.

During centrifugation, the pad-holding unit rests on the bottom of the centrifuge bucket. If this has a semi-spherical bottom, a semi-spherical metal block is used to support the basket. The main function of the metal block is to create a space under the test-pad basket for the removed water.

Annex B

(informative]

Precision

B.1 General

In October 2004, an international round-robin study was performed in which six laboratories from different countries participated.

The calculations have been made according to ISO/TR 24498.

The repeatability and reproducibility limits reported are estimates of the maximum difference which should be expected in 19 of 20 instances, when comparing two test results for material similar to those described under similar test conditions. These estimates cannot be valid for different materials or different test conditions.

NOTE Repeatability and reproducibility limits are calculated by multiplying the repeatability and reproducibility standard deviations by 2,77, where 2,77= 1.96v2.

B.2 Repeatability

Different kinds of pulp samples were tested in one laboratory in accordance with this International Standard. Five to 10 determinations were made in each case. Mean values, standard deviations, and coefficients of variations as well as repeatability limits for each type of sample are shown in Table B.1.

B.3 Reproducibility

Different kinds of pulp samples were tested in six different laboratories in accordance with this International Standard. Mean values, standard deviations, and coefficients of variations as well as reproducibility limits for each type of sample, based on the results of six laboratorles, are shown in Table B.2.